Part of Consumer Guide’s new-car evaluation process includes maintaining a fleet of “extended-use” vehicles. These are cars we drive for six to 12 months to see how they hold up to the grinds of everything from daily commuting to extended road trips.

We’ve sampled many an extended-use Chrysler product over the years, with the versatile 2008 Town & Country minivan and comfy 2012 Dodge Durango among our favorites. The next vehicle to enter our long-term fold is one of the first to result from the brand’s alliance with Fiat. Though its underpinnings are Italian, the styling, name, and point of assembly are all American.

The 2013 Dodge Dart is the company’s attempt to flush the ill-fated 2007-2012 Caliber down the memory hole. We think they’ve done a good job, for the most part. We’ve driven several Dart iterations as part of our standard two-week evaluation process. Though not quite as sporty as a Ford Focus or Mazda 3, Dart scores big points for its quietness, interior design and materials, and high features-per-dollar quotient.

We want to see if these positive attributes will hold up over the course of a yearlong evaluation. Our test Dart of choice is the top-line Limited trim level. Included in its $19,995 base price are a power driver seat, cruise control, rearview camera, and the usual complement of power windows/locks/mirrors and remote keyless entry. To it, we’re adding the optional Premium Group, which adds dual-zone automatic climate control, leather upholstery, heated front seats, heated steering wheel, and remote engine start. Also part of our build is the Technology Group, which adds rear-obstacle detection, keyless entry with pushbutton engine start, rain-sensing wipers, blind-spot alert, and rear cross-traffic alert.

Our car will come with the standard 160-horsepower 2.0-liter 4-cylinder engine, to which we’ve added the extra-cost 6-speed automatic transmission. The 2013 Dart also offers a 160-horsepower 1.4-liter turbocharged 4-cylinder engine, borrowed from the high-performance Fiat 500 Abarth. While the bratty turbo is terrific in the Abarth, we found its raucous character off-putting in the larger, heavier Dart. The 2.0-liter motor is more in keeping with the Dart’s refined nature.

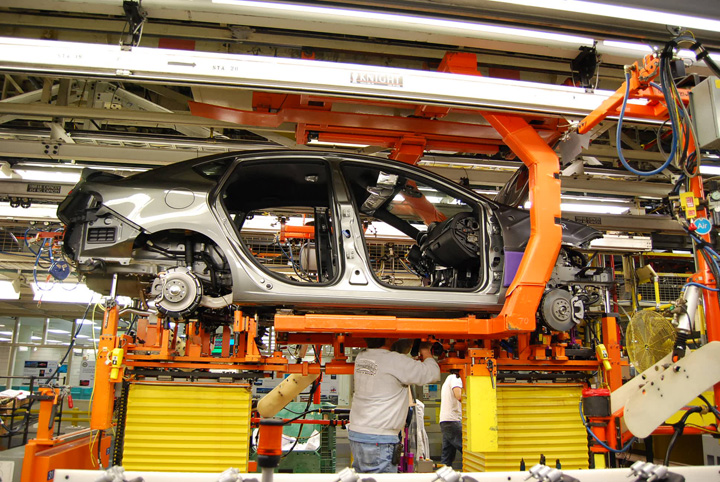

Chrysler assembles the 2013 Dodge Dart in Belvidere, Illinois, a stone’s throw from our suburban Chicago headquarters. The Belvidere plant has been in operation since the mid-1960s. It has produced a number of compact and midsize Chrysler vehicles, notably the Dodge Omni/Plymouth Horizon, Dodge Dynasty/Chrysler New Yorker, and Dodge/Plymouth Neon. In addition to the Dart, the factory makes the compact Jeep Compass and Jeep Patriot. Since this is the only plant that produces these vehicles, the company exports them all over the world, including Europe and China.

The Dart made in Belvidere is for the U.S. market only. Chrysler granted us a rare look inside the factory. We got to follow the exact car we will receive, from its starting point as a body shell to where the finished product drove off the assembly line.

In this first part, we’ll follow our Dart through what Chrysler dubs “Trim and Chassis.” “Trim” is where exterior and interior addenda get bolted to the body, while “Chassis” is where the drivetrain comes into the picture.

“The Man Who Owns One” Madness! 10 Classic Packard Ads

Fahrvergnügen (and 4 Other Obnoxious Automotive Marketing Terms)

Meet the Millionth Porsche 911

Luckless Irish: Remembering the 1959 Shamrock